DataMax.

Faster Concrete Works.

Lower Cost, Lower Carbon.

World's Smartest IOT & AI

Solutions For Concrete

We Are the Largest & Most Trusted Provider Of Data For Asia's Concrete Construction Industry

Our IOT devices, software & AI tools deliver affordable, real time insights, making every concrete project less expensive, faster and higher in quality.

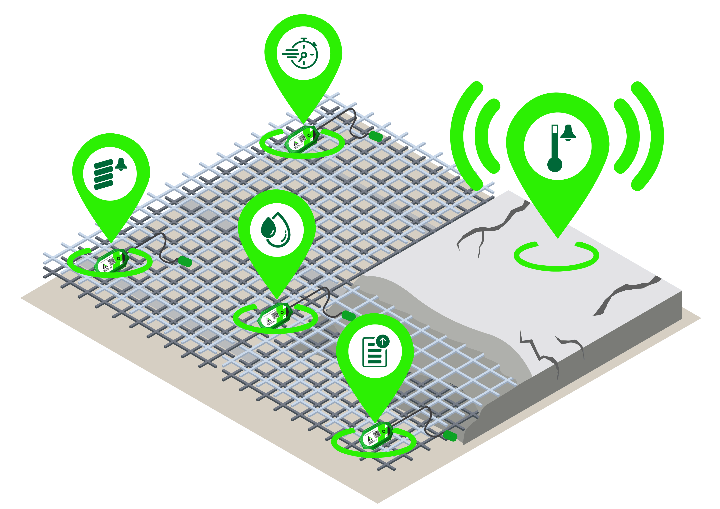

At the heart of of the BetonAnalytica System is the DataMax Sensor. The worlds most powerful, fully embedded concrete sensor that measures insitu concrete temperature, compressive strength and humidity.

These small, affordable and powerful relays are placed around the jobsite above ground to constantly stay connected to your concrete night and day. They continuously monitor and relay signals from each unique embedded sensor to the Cerebro Base Station.

Data from every sensor and relay finds its way safely here. This powerful communication and data storage device serves as a complete back up for your project on site. Every 15 minutes it completely uploads to the cloud via regular 3G signal or our unique Satellite Phone system.

How Does It Work

Its Simple As ABC

Either we can set up for you, or by following our simple instructions, you can set up yourself, in no time at all.

A. Scan the sensor barcode

B. Locate sensor on rebar.

C. Pour concrete.

Get results.

It’s as strong as it is easy to use.

Digitized Concrete

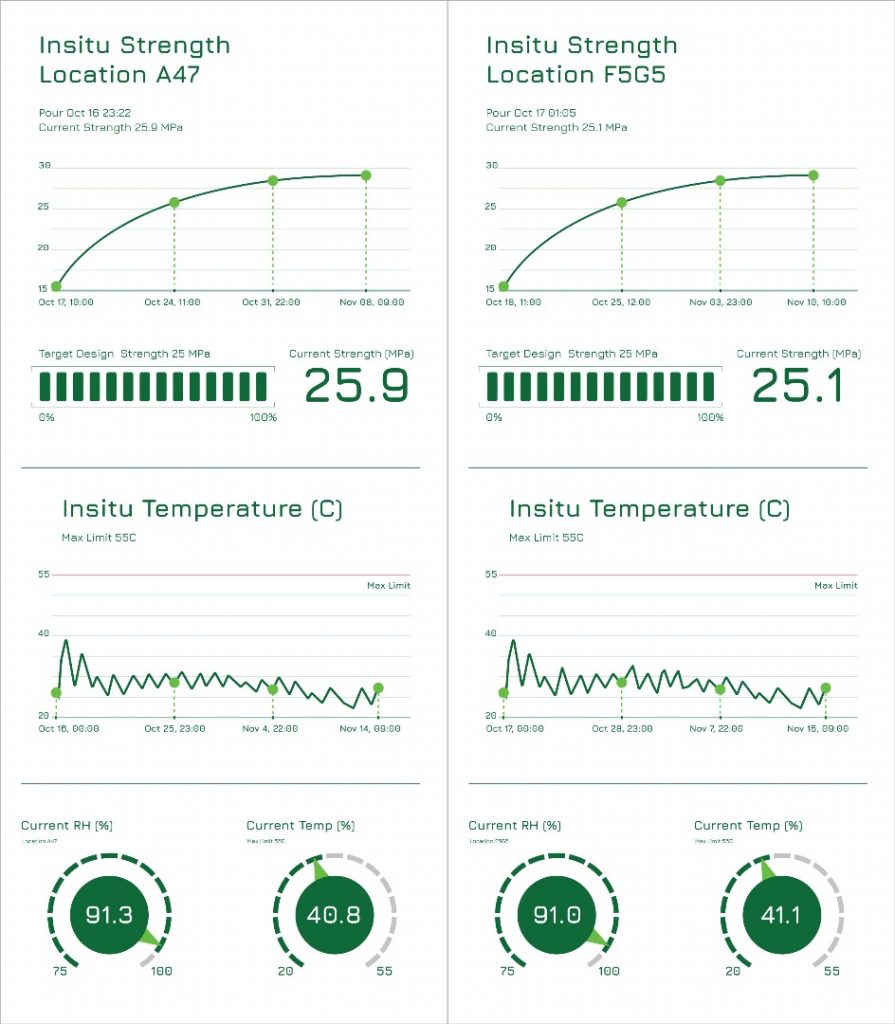

Know the status of your concrete works 24-7. Use your data to remove formwork and scaffolding the exact moment you reach target strength.

Cut your costs, secure resources only when you need them. Set up notifications on your device to alert you when its time to strip. Simple. Reliable.

No more waiting.

No more wasted resources.

Finish your projects weeks early.

Working Together Works

High performing construction teams need one source of the truth.

Concrete strength or temperature planning is easy teamwork with DataMax.

All team members can have access to the same real-time data, alerts & insights.

One point of information, easy report sharing, no waiting, error free, real time.

Eliminate Concrete Testing Delays

And Reduce Concrete Testing Costs

Traditional cylinder crush testing across a project, is expensive, slow, repetitive work that is easily replaced and improved – by accurate DataMax sensors.

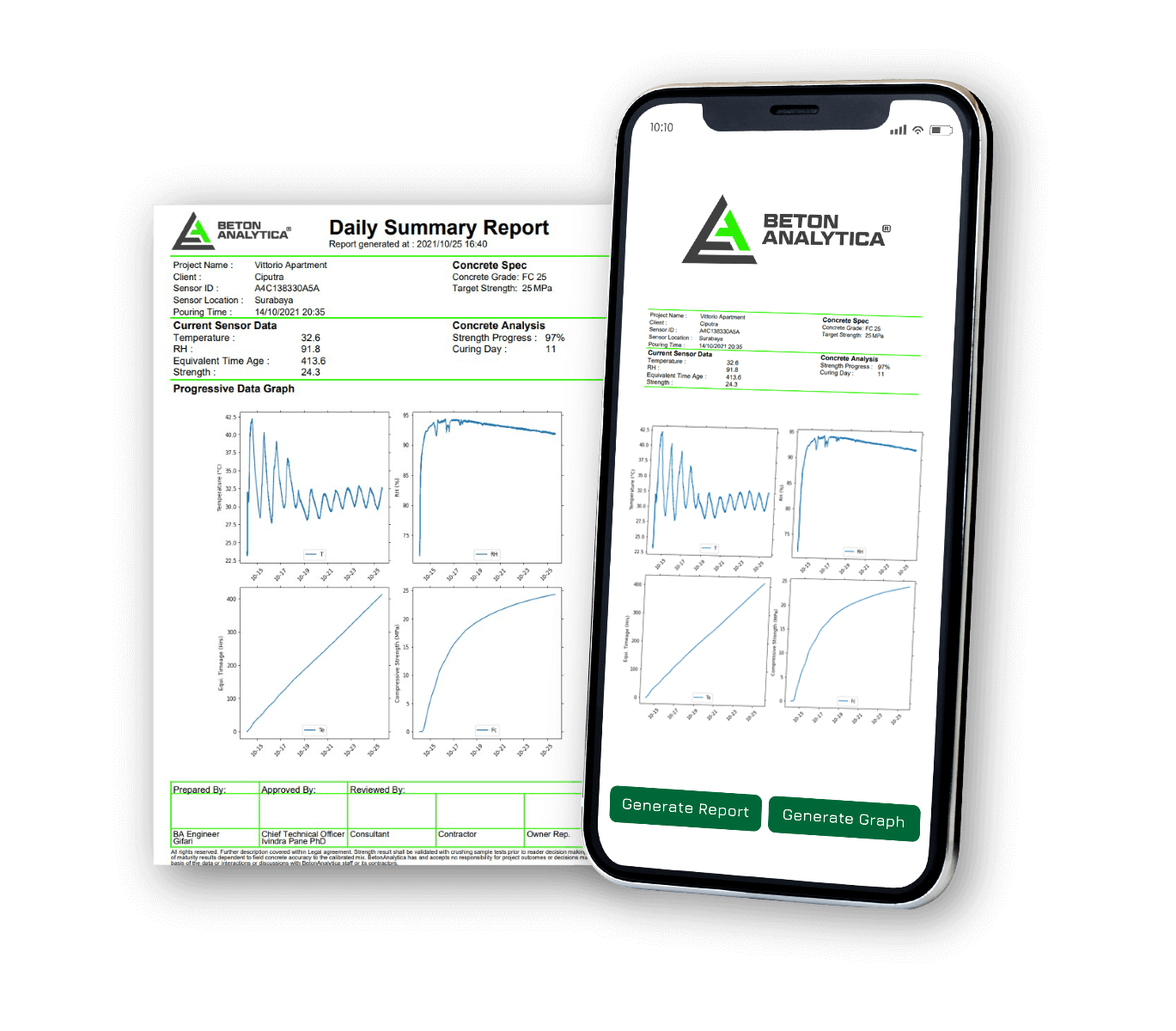

The Maturity Method used by BetonAnalytica is an approved, accurate and reliable concrete testing method. Faster and more reliable than field cured cylinders, the method compares data from your insitu sensors to our pre-calibrated result of your concrete to deliver immediate results for quick decision making and predictive modelling.

Faster, safer, less error phone and more reliable strength & cure results, saving days per section and weeks on projects.

Reduce Heat Damage & Cracking

Monitoring concrete temperature is critical to ensure proper strength development. Excessive heat reduces strength, impacts curing and damages concrete finish.

In mass concrete – understanding temperature differentials between a hot core and a cooler surface allows site teams to take action to avoid low strength structures.

High surface temperature in concrete roads, impacts cutting and grooving time. Real time temperature monitoring allows correct estimation of setting time and times to initiate cuts.

Predict How Your Concrete Will Perform

BetonAnalytica is built around our Machine Learning & Artificial Intelligence engine.

With your sensor data in the engine – you can closely predict how your concrete projects will perform. This allows you to mobilize resources when needed – not earlier – not later for perfect results.

We can also combine local weather data, concrete types, seasonal conditions and our database of concrete pours to your data, so your engineers can plan site activities like never before. Your projects will be smoother, less costly and your concretes will be delivered faster & at higher quality

Leverage Your Digital Twin

BetonAnalytica combines state of the art sensors, machine learning and affordable software platforms to make full use of your BIM engineering platforms.

Scale construction projects are increasingly digitized at the plan stage and resolved via digital twins. Data from BetonAnalytica Sensors provides a digital expression of your concrete works. Output data is designed to be incorporated into most existing digital twin platforms, bringing new tools to evaluate & visualize project status, contractor performance, materials cost & optimizations.

The heart of the BetonAnalytica System is a construction model built off Machine Learning & Artificial Intelligence that tracks and reports your project in real time and brings actionable insights & comparisons. Open roads faster, strip forms & remove expensive scaffolding sooner.

What Do We Do ?

BetonAnalytica is The Largest Provider of Data Services to The Concrete Construction Industry in Asia Pacific

Based In Jakarta, Singapore & Hong Kong, we develop and provide a full range of IOT sensor devices and application software platforms to log, read and manage data from concrete projects large and small. We understand the hot, wet and challenging conditions across Asia Pacific and we back up our services with sophisticated in market laboratories and technical staff. We independently calibrate and field validate our projects. At the heart of the BetonAnalytica System is the DataMax Sensor. The worlds most powerful fully embedded concrete sensor. It’s the surest & most affordable way to measure strength and curing conditions on any jobsite.

Asia Pacific is The World Largest & Fastest Growing Construction Market. Our Mission Is To Bring Efficiency, Lower Cost, Manageable Insights To Construction Leaders By Digitizing Concrete & Concrete Placement

We Use Sensor Data, AI Engines & Data Analytics To Transform Concrete Projects

BetonAnalytica

Intelligent Encrypted IoT Sensors & Telemetry

Mix Design & Batching Plant expertise

Artificial Intelligence, Machine Learning & SaaS

Cloud Computing, Mobile Applications

Laboratory Facilities & Validations

Direct Customer Sales Solutions

Who We Are

BetonAnalytica is a diverse team of software specialists, electronics engineers, concrete scientists and specialists in HR, Procurement, Finance and Logistics.

We speak Mandarin, Cantonese, Indonesian, Bahasa Melayu and sometimes, English.

Who Are Our Founders

Lenny Sam

Chris O'Donohue

What Our Customers Say